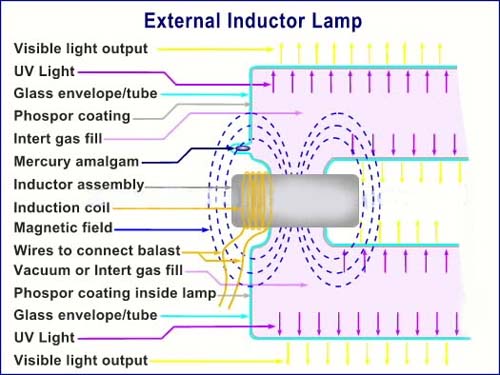

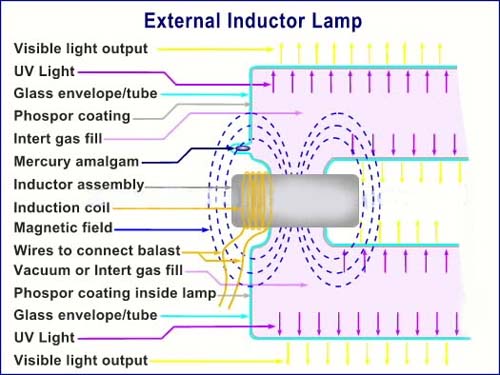

Magnetic induction lamps are basically fluorescent lamps with electromagnets wrapped around a part of the tube, or inserted inside the lamp. In external inductor lamps, high frequency energy, from the electronic ballast, is sent through wires, which are wrapped in a coil around the ferrite inductor, creating a powerful magnet.

The induction coil produces a very strong magnetic field which travels through the glass and excites the mercury atoms in the interior which are provided by a pellet of amalgam (a solid form of mercury). The mercury atoms emit UV light and, just as in a fluorescent tube, the UV light is up-converted to visible light by the phosphor coating on the inside of the tube.

The system can be considered as a type of transformer where the inductor is the primary coil while the mercury atoms within the envelope/tube form a single-turn secondary coil.

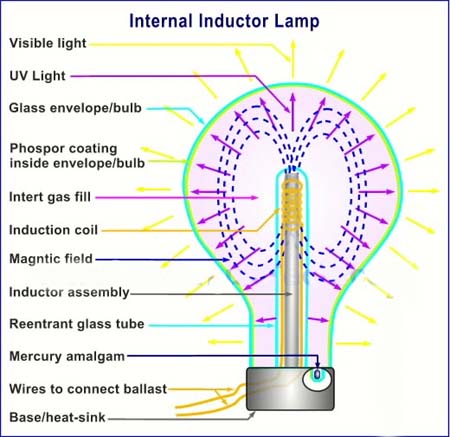

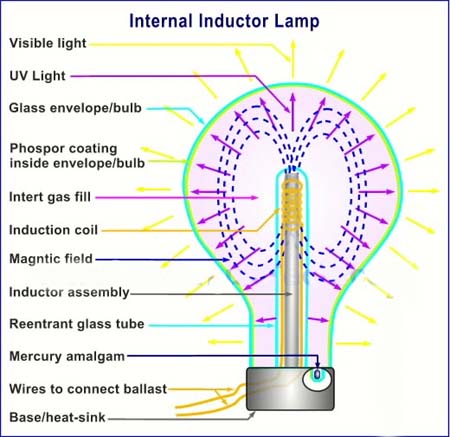

In a variation of this technology, a light bulb shaped glass lamp, which has a test-tube like re-entrant central cavity, is coated with phosphors on the interior, filled with inert gas and a pellet of mercury amalgam. The induction coil is wound around a ferrite shaft which is inserted into the central test-tube like cavity.

The inductor is excited by high frequency energy provided by an external electronic ballast causing a magnetic field to penetrate the glass and excite the mercury atoms, which emit UV light, that is converted to visible light by the phosphor coating.

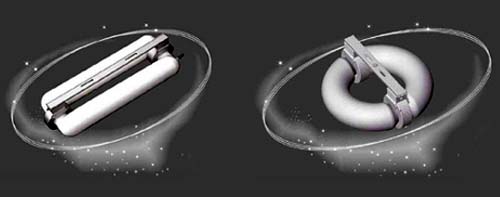

The external inductor lamps have the advantage that the heat generated by the induction coil assemblies is external to the tube and can be easily dissipated by convention into the air, or conduction into the fixture. The external inductor design lends itself to higher power output lamps which can be rectangular or doughnut shaped. In the internal inductor lamps, the heat generated by the induction coil is emitted inside the lamp body and must cool by conduction to a heat-sink at the lamp base, and by radiation through the glass walls. The internal inductor lamps tend to have a shorter lifespan than the external inductor types due to higher internal operating temperatures. The internal inductor type looks more like a conventional light bulb than the external inductor type lamps which may be more appealing in some applications.

As with conventional fluorescent lamps, varying the composition of the phosphors coated onto the inside of induction lamps, allows for models with different

color temperatures. The most common color temperatures of induction lamps are 3500K, 4100K, 5000K and 6500K.

Induction lamps require a correctly matched electronic ballast for proper operation. The ballast takes the incoming mains AC voltage [or DC voltage in the case of 12V and 24V ballasts] and rectifies it to DC. Solid state circuitry then converts this DC current to a very high frequency which is between 2.65 and 13.6 MHz depending on lamp design.

This high frequency is fed to the coil wrapped around the ferrite core of the external or internal inductor. The high frequency creates a strong magnet field in the inductor which couples the energy through the glass walls of the lamp and into the mercury atoms inside the tube.

The ballasts contain control circuitry which regulates the frequency and current to the induction coil to insure stable operation of the lamp. In addition, the ballasts have a circuit which produces a large ?start pulse? to initially ionize the mercury atoms and thereby start the lamp. The induction lamps do not start at 100% output - they start at between 75% and 80% output. It takes between 60 and 120 seconds for the mercury bearing amalgam in the lamp to heat up and release enough mercury atoms for the lamps to reach 100% light output.

The close regulation of the lamp by the ballast, and the use of microprocessor controlled circuits allows the ballasts to operate at around 98% efficiency. Only around 2% of the energy is wasted in the induction lamp ballast compared to the 10-15% wasted in traditional ?core and coil? type designs used with most high output commercial and industrial lighting.

Download Complete LVD Induction Lights Technical Details, Specification & Cost Analysis Broacher

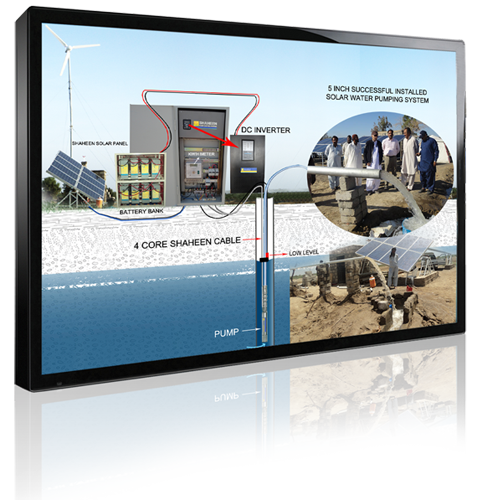

state-of-the-art designSolar Water Pumping System

state-of-the-art designSolar Water Pumping System Wind Power Use itdon't let it blow away!

Wind Power Use itdon't let it blow away!

Most Experienced inSolar, Wind and Hybrid Technology

Most Experienced inSolar, Wind and Hybrid Technology SOLARBattery BanksShaheen Enterprise

SOLARBattery BanksShaheen Enterprise Water PUMP SystemShaheen Enterprise'sFeature Project

Water PUMP SystemShaheen Enterprise'sFeature Project